MATT IT IS!

09.04.2019

These days, if you look at the cosmetics sector or the electronics sector, for example, you will notice that the majority of the latest generation products have one thing in common: they all have a matt finish.

Pinneberg/Germany, April 9th, 2019 – Modern consumers regard matt surfaces as premium quality and elegant, which is why they are increasingly in demand. In this respect, ROMIRA is the ideal partner due to its already established products and current developments.

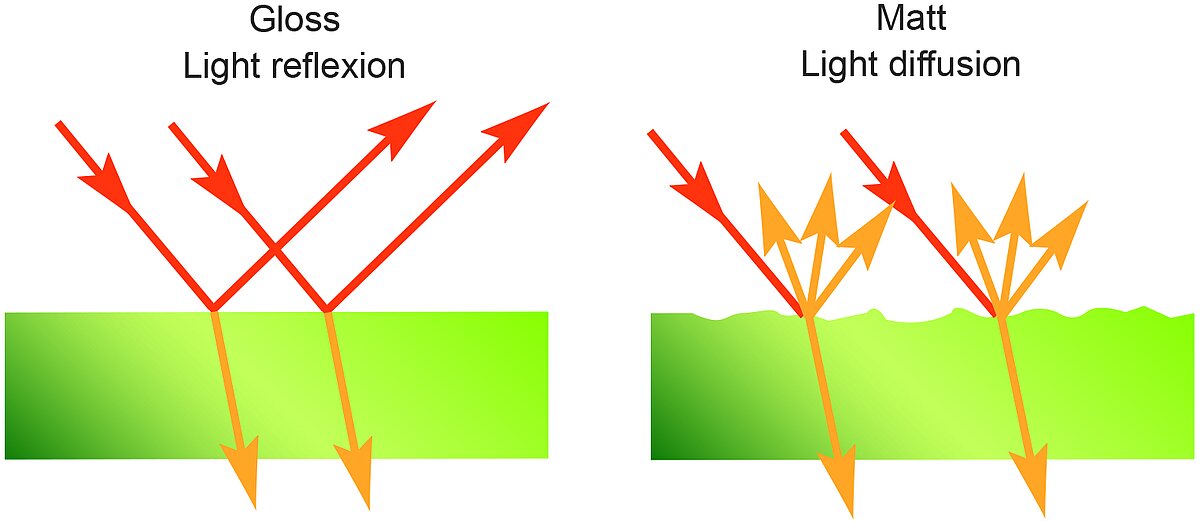

A matt appearance is created by light scattering on a materials surface and can be created as a result of surface roughness. Unlike high-gloss surfaces, a rough or uneven surface reflects the light diffusely and this causes the observer to perceive the object as matt. There are two physical processes for creating uneven surfaces: firstly, a pre-treatment of the tool, i.e. etching the surface of the tool, or secondly, an appropriate post-treatment of the molded component by applying a matt finish. However, both processes involve additional work – a tool modification or additional painting.

A matt finish can also be produced solely by material selection. By introducing suitable additives into the polymer, rough surfaces are created on a microscopic level, which results in a matt appearance on the plastic surface. ROMIRA offers optimum material solutions for this purpose, which enables a matt finished surface to be produced, even in high-gloss molds.

In the case of transparent materials such as polycarbonate, diffused reflection of light can be caused by introducing scattering centers, i.e. particles with a different refractive index to that of the base material. This leads to a reduction or loss of transparency and a translucent, matt effect.

The matt compound options offer several compelling benefits: reduction of work steps by eliminating the painting process and tool modifications, together with production efficiency gains and important financial savings. ROMIRA already has several inherently matt products in its portfolio and is working intensively on further developments in this field. The range of applications from construction and automotive, to the consumer goods industries is already highly extensive.