ROMILOY® exhibits high material resistance

16.08.2021

Disinfect without risk: Since the start of the Corona pandemic, disinfecting plastic surfaces has become a continuous task in our daily lives, whether in shops, offices or our own homes. This has brought about the issue of stress cracking, which was previously mostly important in the medical sector, but has now become relevant for many ordinary items of daily use, such as shopping carts. ROMIRA has tested selected compounds for their material compatibility with disinfectants so that customers can be assured of the usual high quality in response to these new demands.

Pinneberg/Germany, August 2021 – Plastics must be able to withstand a wide variety of different requirements, depending on where they are used. For disinfectants, these requirements include the user (layperson, specialist), the duration of application and the active ingredient (e.g. alcohols, aldehyde or ammonium compounds [Quats]). The standards DIN EN ISO 175 and DIN EN ISO 22088-3 are used to test the compatibility of plastic materials with media, in particular disinfectants.

A significant difference between the two tests is that in the DIN EN ISO 22088-3 measurement, the test bar is clamped with a defined bending. Moreover, the standard test time of 24 hours is shorter than that of DIN EN ISO 175, which is one week. And DIN EN ISO 22088-3 specifies the formation of stress cracks as a failure criterion, while DIN EN ISO 175 is based on a change in weight or mechanical tests.

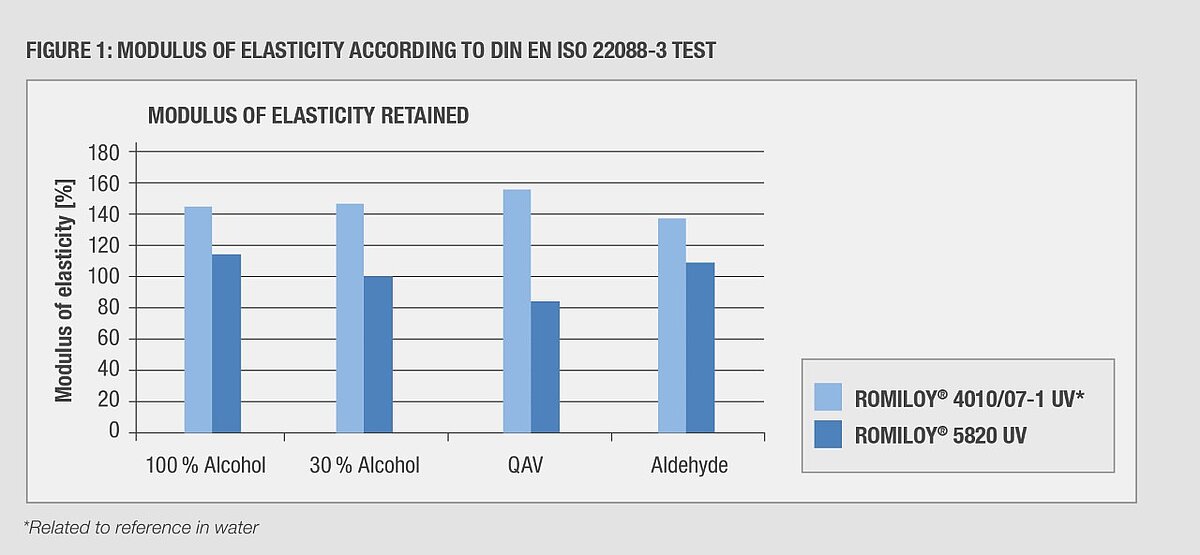

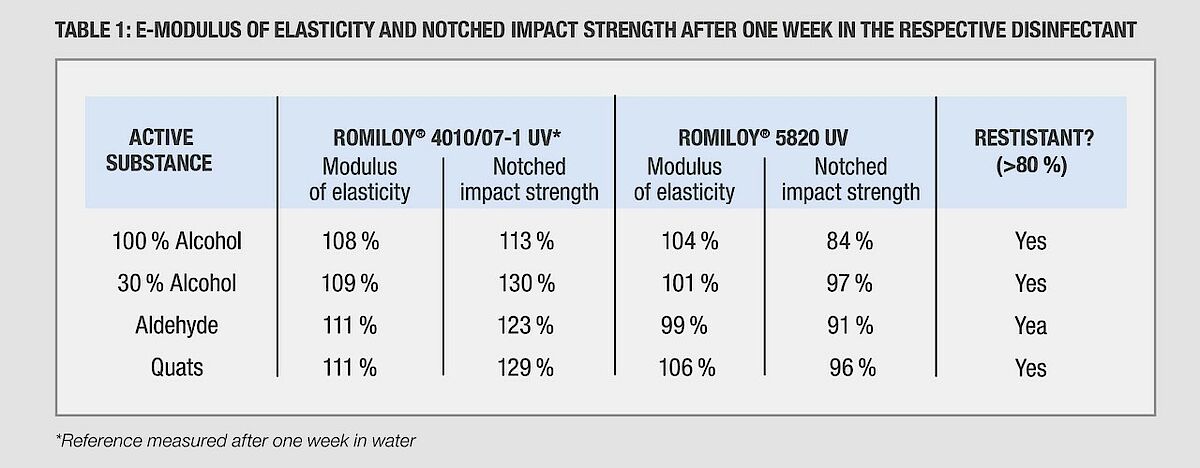

ROMIRA has tested both ROMILOY® compounds 4010/07-1 UV and 5820 UV according to DIN EN ISO 175 and DIN EN ISO 22088-3. These two compounds are used by our customers in the medical technology sector. The results of the test according to DIN EN ISO 175 are shown in Table 1.

After one week in the respective disinfectant, both ROMILOY® 4010/07-1 UV and ROMILOY 5820 UV continue to exhibit more than 80% of the original modulus of elasticity or notched impact strength and are consequently resistant.

The stress cracking resistance of the two compounds was determined according to DIN 22088-3 in addition to their general resistance. Even after 48 hours, twice the specified standard time, no stress cracks occurred in the material. The modulus of elasticity of the specimens tested according to DIN EN ISO 22088-3 was then determined (see Figure 1). As with the test according to DIN EN ISO 175, at least 80% of the original modulus of elasticity remains.