HIGH FUNCTIONALITY AND DESIGN FREEDOM

29.04.2021

Additional areas of application for ROMILOY® ASA/PA A competent manufacturer of engineering thermoplastics, ROMIRA is renowned in the plastics industry and in particular in the automotive sector as a reliable partner for efficient and application-specific material solutions. The company offers materials with tailor-made properties depending on the customer‘s requirements, fulfilling not only the technical requirements of automotive standards but also the functional and design aspects.

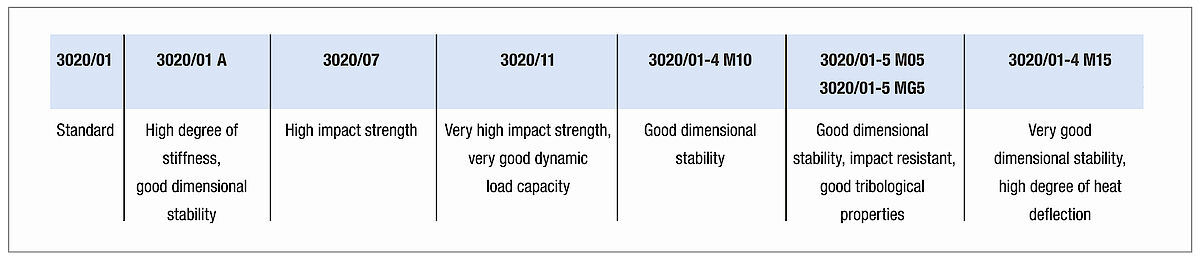

Pinneberg/Germany, April 29th, 2021 – A perfect and latest example of this is the ROMILOY® 3020 - ASA/PA blends series. OEMs and fabricators alike highly value these blends and apply them in a variety of ways, particularly where decorative parts with function are required, such as complex part geometry combined with high safety requirements: I-panel covers, pillar trim, speaker grilles, seatbelt outlet trims as well as seatbelt guides and child restraint parts are just a few automotive interior examples.

The air outlet trim in the dashboard is a new area of application in which the ROMILOY® ASA/PA blend has recently proved its worth. In addition to the sophisticated visual impression that is always required in interiors, it is of particular importance here that the material complies with the high requirements of heat deflection resistance and UV resistance, something that is ensured by the UV-resistant ASA component.

Alongside the excellent balance of technical properties, the good tribological properties are also significant: The crystalline polyamide component as well as the addition of suitable additives boost the good tribological properties of ROMILOY® ASA/PA blends even further, resulting in excellent sliding properties and a natural noise-damping effect. These greatly valued aspects in the automotive industry can be achieved particularly well with the ROMILOY® 3020/01-5 MG5 blend. As a result of the high performance coloring, ROMIRA is able to produce complex tones and paler shades with the color consistency that is required.

ROMIRA also further contributes to improving the injection molding process for fabricators: Originally, polyamide-containing compounds had a tendency to form deposits depending on the sprue design, flow path conditions, grain and mold geometry or residual moisture in the material, so that the molds had to be cleaned regularly to prevent deterioration in quality.

This situation has already been resolved by ROMILOY® ASA/PA compounds and, following further technology optimization, the time window that allows parts to be produced by injection molding without cleaning has now also been extended.

The list of advantages of the ROMILOY® 3020 product series also includes excellent chemical resistance and a striking look and feel to textured surfaces without subsequent coating. The products are also permanently antistatic by nature, and the outstanding dynamic load-bearing capacity of ROMILOY® 3020/11 for parts with high safety requirements is particularly noteworthy.